Users/Telanoc/Gears

The Basics

A Beginners Guide to Gearbox Design. You can find the computed Gear Ratios here: Gearbox Ratios

Gear Ratios

Every gearbox will have one to three listed outputs. The requirements will list the output column and a range of ratio values. For example, "D90-D110". Any output in that column must be within that range, inclusive of the top and bottom numbers, to be acceptable. The lower the output ratio value, the smaller the range will be. The higher the output ratio value, the larger the range will be.

Notation Conventions

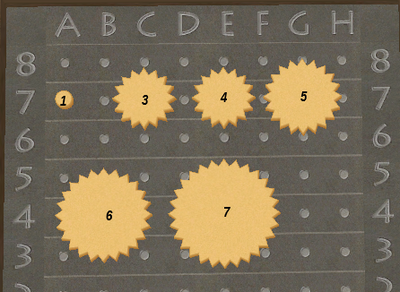

- A shaft location will be denoted by its row and column, for example 8C is the top row, third from left

- When discussing gear ratios a “/” denotes one gear that meshes with and turns another. For example 5/3

- When discussing gear ratios a “*” denotes two gears that share a single shaft. For example 3*5

- An example would be 5/3*6/5/3. This means a 5 tooth gear turning a 3 tooth gear. On the same shaft as that 3 tooth on a different layer is a 6 tooth gear, which turns a 5 tooth gear, which then turns a 3 tooth gear

The Rules and Concepts

The Gearbox Design Table

- Every gearbox must start at “1A” (the lower left hand corner as you face the gearbox)

- Every gearbox must have at least one, but no more than three outputs in the top row (Row 8)

- You may use up to, and no more than, thirty (30) gears in your gearbox

- You may use up to, and no more than, fifteen (15) shafts in your gearbox. A shaft is a row and column intersection that has one or more gears (e.g. 2B)

- There are three layers in a gearbox. Gears can only mesh when they are on the same layer. The input and output layers don't matter.

- There are eight rows numbered 1 to 8

- There are eight columns numbered A to H

Gear Sizes and Arrangements

An explanation of which metals are used when

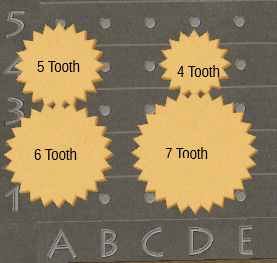

- Gears come in 1,3,4,5,6, and 7 tooth.

- 1 tooth is a “Spacer”, and costs no materials. However, it does count for your gear total. Size 1 Spacers do not mesh with other gears. The purpose is to allow you to move up on a shaft, usually to avoid clashing with other gears.

- 3 and 4 are considered “Small Gears”, and will cost 2 debens of metal to cast.

- 5 and 6 are considered “Medium Gears”, and will cost 15 debens of metal.

- 7 is considered a “Large Gear”, and will cost 100 debens of metal

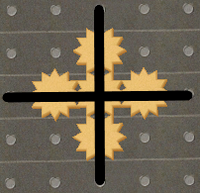

- The sum of adjacent gears in the horizontal or vertical axis must be 6. Therefore, only 3/3 is valid when moving one space in either the horizontal or vertical axis

- The sum of adjacent gears in the diagonal axis must be 8. So 4 and 4, 5 and 3 are valid configurations.

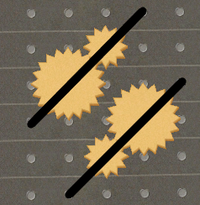

- The sum of the gears in the horizontal or vertical axis that are separated by one space (so not adjacent) must be 11. Therefore, valid configurations are 6 and 5, 7 and 4

- The sum of the gears in a “Knight’s move”, which is to say two space away and one off the axis, must be 12. Therefore 6 and 6 or 7 and 5 are valid pairs.

Basic Understaing of Ratios

- Whenever a gear turns another gear, it is a ratio based on the fraction created from the number of teeth.

- If a larger fear turns a smaller gear, the output value increases. For example, if a 5 tooth turns a 3 tooth, the output will be increased by 67% because five thirds (5/3) is equal to 1.67.

- If a smaller gear turns a large gear, the output value decreases. For example, if a 3 tooth turns a 5 tooth, then the output will be 60% of the input because three fifths (3/5) is equal to 0.6.

- If a gear turns another gear of the same size, the output value remains the same. For example, if a 3 tooth turns a 3 tooth, then the output will be the same as the input because three thirds (3/3) is equal to 1.

Tricks and Tips

- If you have a multiple output gearbox, see if one or more the ranges overlap. For example, if the requirement is A90-A120 C95-C125 G80-G110, a single ratio of 100 will satisfy all three requirements. This will greatly simply your design process

- If you have a multiple output gearbox, and not all of the ranges overlap, or none of them do, look for ratio chains that use the same sets of gears. For example, you have a gearbox that is A150-A180 and F310-F340. Clearly, neither of those ranges overlap. But if we lookup at the ratios in those ranges we see that 167 uses a 5/3 gear set and 333 uses a 5/3*6/5/3 gear set. Therefore, we can use a 5/3 set for both ratios, thus saving us gears and shafts.

- If you have a multiple output gearbox and none of the ranges overlap, nor do any of ratio chains, look for chains with the fewest gears and shafts. Not only are you limited by the total number of gears and shafts, you also have to fit it all in an eight by eight grid. Use as little space as possible for each chain.

- Since the gears are simple math, you can increase ratios and then decrease them. To give an example, say we had the reserve of the above gearbox requirements, A310-A340 and F150-F180. You could use the chain of 5/3*6/5/3 to get to A333, and then from the last 3 tooth gear put a set of 3/5/6, giving a total of 5/3*6/5/3/5/6. This actually a horrible example, and is used only to illustrate the point.

- Try to avoid using 7 tooth gears. Not only are they much more expensive than other types, they are harder to work around. If you must use one, try to put it on either layer 2 or 3 where it is more likely to be out of the way.

- Even if you are only making a "simple" single output gearbox, practice making efficient designs. For example, finding ways to reduce gear and shaft counts. You will develop habits that will serve you well when you have to make more complex gearboxes when every gear and shaft will be needed.

- The hardest gearboxes to make are ones that are "High-Low-High", which is to say it has a high range, then a low range, then another high. For example A470 C80 G400. If it is for something where you can re-roll the requirements, it might be wise to do so.

- Gear chains can be broken up. For example, 6/5/3 is a 6 tooth turning a five tooth turning a three tooth. Doing 5/3*6/5 would result in the same output, but use more gears. You might want to do this when you can make overlapping chains. For example, 333 is 5/3*6/5/3. But if you need to pair is with 200 (6/5/3), you might consider 6/5/3*5/3

- If you get stuck, don't be afraid to ask others. Even the most experienced gearbox makers get stumped sometimes.